Hydroxypropyl Methyl Cellulose Ether (HPMC) is a versatile, water-soluble polymer derived from cellulose, widely used across industries for its unique functional properties. This semi-synthetic compound is produced by treating cellulose with propylene oxide and methyl chloride, resulting in a material that combines thermal gelation, film-forming ability, and adjustable viscosity. HPMC is non-ionic, odorless, and tasteless, making it ideal for applications requiring stability and biocompatibility.

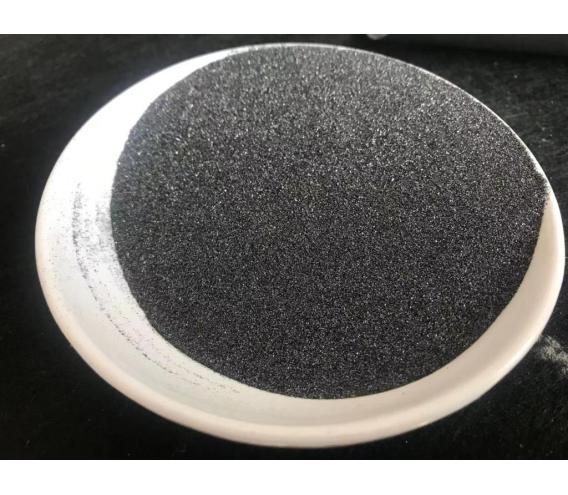

(hydroxypropyl methyl cellulose ether)

In construction, HPMC acts as a critical additive in cement-based products. It improves workability, water retention, and adhesion in mortars, tile adhesives, and renders. By slowing water evaporation, it enhances curing efficiency and reduces cracking. Its thickening properties also aid in sag resistance, ensuring even application on vertical surfaces.

The pharmaceutical industry relies on HPMC as an excipient in tablets and capsules. It functions as a binder, disintegrant, or controlled-release agent, ensuring precise drug delivery. Its biocompatibility and inert nature make it safe for oral and topical formulations. In ophthalmic solutions, HPMC serves as a lubricant, providing sustained moisture for dry eye relief.

Food-grade HPMC is a popular additive, acting as a thickener, emulsifier, or stabilizer in products like sauces, dairy alternatives, and gluten-free baked goods. It enhances texture without altering flavor and meets strict safety standards.

Personal care products, including shampoos, lotions, and creams, utilize HPMC for its emulsifying and film-forming properties. It improves product consistency, provides a smooth feel, and stabilizes formulations against temperature changes.

Key advantages of HPMC include its non-toxic profile, biodegradability, and compatibility with other chemicals. It is pH-stable, performing reliably in acidic or alkaline environments. Manufacturers value its customizable viscosity grades, allowing precise tailoring for specific applications.

(hydroxypropyl methyl cellulose ether)

As industries prioritize sustainable and high-performance materials, HPMC remains a go-to solution. Its adaptability, safety, and efficiency ensure continued demand in construction, pharmaceuticals, food, and cosmetics. For formulators seeking a multifunctional additive, HPMC delivers unmatched versatility and performance.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)