Indium Tin Oxide, universally known as ITO, is the invisible workhorse behind modern displays. This transparent conductive oxide combines two key properties exceptionally well: optical transparency and electrical conductivity. Typically composed of around 90% indium oxide and 10% tin oxide, ITO forms thin films crucial for countless electronic devices.

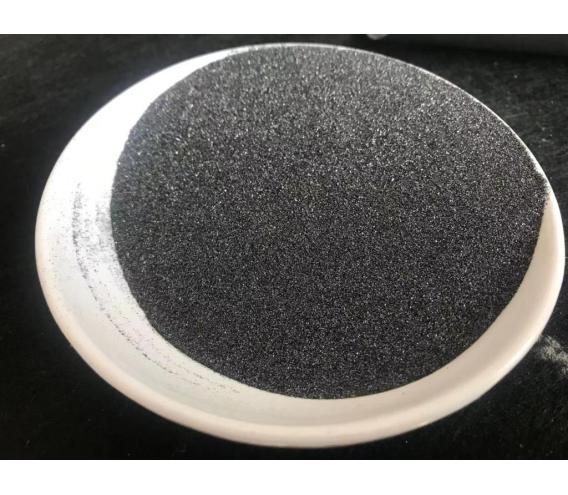

(ito indium tin oxide)

Its primary magic lies in allowing light to pass through while simultaneously conducting electricity. This unique combination makes ITO indispensable for touchscreens on smartphones, tablets, and laptops. When you touch the screen, the ITO layer detects the change in electrical current at that precise location. Similarly, in liquid crystal displays (LCDs) and organic light-emitting diode (OLED) screens, ITO electrodes form the transparent conductive layer that controls the pixels, enabling the vibrant images we see.

Beyond displays, ITO finds use in solar cells, acting as the transparent front electrode that collects generated electricity while letting sunlight in. It’s also used in electrochromic windows (smart windows that change tint), gas sensors, and electromagnetic shielding. The material is usually deposited as a thin film onto glass or plastic substrates using techniques like sputtering.

(ito indium tin oxide)

However, ITO isn’t without challenges. Indium is a relatively rare, expensive element, raising concerns about long-term supply and cost, especially as demand for electronics grows. Processing ITO films often requires high temperatures, limiting its use on flexible plastic substrates. Finding alternatives with comparable performance and lower cost or greater flexibility is a major research focus. Materials like silver nanowires, graphene, conductive polymers, and other transparent conductive oxides are actively being explored. Despite these challenges, ITO remains the dominant transparent conductor due to its proven performance and established manufacturing processes, underpinning the visual interface of our digital world.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)