Nickel Manganese Oxide represents a crucial class of materials, particularly within advanced battery technology. Often referred to as NMO or specifically as spinel nickel manganese oxide (NiMn₂O₄), its unique crystal structure delivers valuable properties. Its most significant impact lies in lithium-ion batteries, forming the foundation of popular NMC (Nickel Manganese Cobalt Oxide) cathodes.

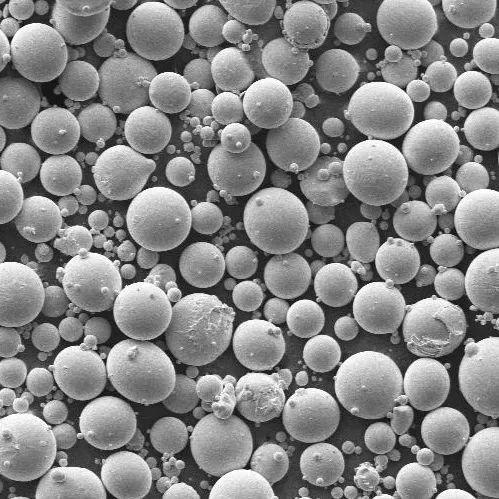

(nickel manganese oxide)

These cathodes, combining nickel, manganese, and cobalt in varying ratios (like NMC 111, 532, 622, or 811), leverage the strengths of nickel manganese oxide. Nickel provides high specific capacity, boosting energy density for longer range in electric vehicles and extended runtime for electronics. Manganese contributes essential structural stability and thermal safety while lowering material costs. Cobalt enhances rate capability and cycle life but is expensive and ethically challenging.

The synergy within NMC cathodes offers a compelling balance: high energy density, good power capability, reasonable lifespan, and improved safety compared to older cobalt-rich cathodes. Reducing cobalt content by increasing nickel and manganese is a major industry trend, lowering costs and supply chain risks. Research continuously optimizes the Ni:Mn ratio and explores coatings or dopants to further enhance performance, especially cycle life and stability at high voltages.

(nickel manganese oxide)

Beyond lithium-ion batteries, nickel manganese oxide finds niche applications. Its electrical properties make it suitable for certain types of thermistors and sensors. Its catalytic activity is explored for chemical processes. However, the battery sector remains its dominant application area, driving global research and development. The push for sustainable energy storage solidifies nickel manganese oxide’s role as a key enabler for electrified transportation and grid storage solutions. Continued innovation focuses on maximizing performance while minimizing cost and environmental footprint.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)