Concrete foaming agent powder is a vital additive used to create lightweight cellular concrete. This dry powder generates stable, uniform air bubbles when mixed with water and introduced into a cement slurry under mechanical agitation. The primary function is to produce controlled foaming within the concrete mix. This process significantly reduces the density of the final hardened concrete while maintaining structural integrity.

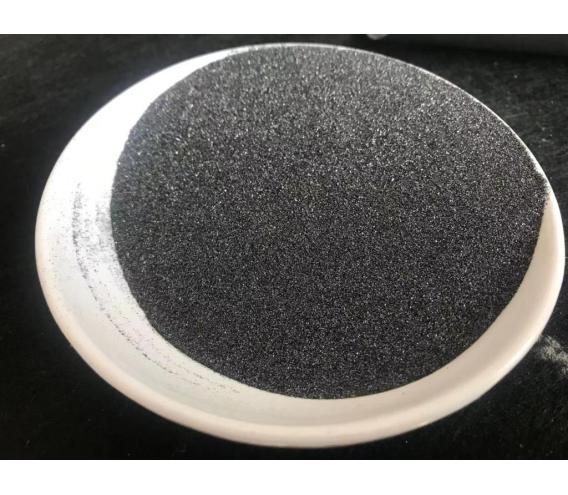

(concrete foaming agent powder)

The key mechanism involves the surfactant properties of the powder. When dissolved in water and agitated, it lowers surface tension, allowing air to be trapped and forming millions of microscopic, resilient bubbles throughout the mixture. These bubbles remain intact during pouring and curing, creating a matrix of air voids. This results in lightweight concrete with excellent thermal insulation properties and reduced dead load on structures.

Benefits are substantial. Foamed concrete offers improved workability, enhanced fire resistance, and superior sound absorption compared to traditional concrete. It reduces material costs by lowering cement consumption and minimizes structural weight, ideal for precast panels, void filling, roof insulation, and backfilling applications. The powder form ensures easy storage, transportation, and precise dosing on-site, avoiding the handling issues of liquid agents.

Applications span construction sectors. It’s essential for lightweight blocks, floor screeds, tunnel grouting, and soil stabilization projects. The powder enables consistent foam quality, crucial for achieving target densities and strength classes in diverse mixes.

(concrete foaming agent powder)

For optimal results, strictly follow manufacturer dosage guidelines. Overuse can weaken concrete; underuse may not achieve desired density. Always blend the powder thoroughly with water to form a stable foam before adding to the mix. Use high-shear mixing equipment to ensure bubble uniformity. Test small batches first to confirm compatibility with local cement and aggregates. Store powder in a cool, dry place to prevent moisture absorption and clumping. Proper handling guarantees efficient, high-performance foamed concrete every time.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)