Tungsten oxide is an inorganic compound primarily existing as tungsten trioxide (WO3) or tungsten dioxide (WO2). WO3 is the most common and stable form, appearing as a yellow powder or ceramic. WO2 is a brownish solid. Both exhibit fascinating properties driving diverse applications. A key characteristic is electrochromism. Tungsten trioxide changes color reversibly, typically from transparent to deep blue, upon the insertion of ions and electrons when a small electric current is applied. This makes WO3 the critical active layer in smart windows, which dynamically control light and heat transmission in buildings, enhancing energy efficiency. Tungsten oxide is also a significant photocatalyst. Under light, especially ultraviolet, it can accelerate chemical reactions, notably the breakdown of organic pollutants in air or water, contributing to environmental cleanup efforts. Its chemical sensitivity extends to gases. Changes in electrical resistance when exposed to specific gases like nitrogen oxides or hydrogen sulfide enable its use in gas sensors for environmental monitoring or safety systems. Tungsten oxide nanoparticles find roles in advanced coatings and as additives in certain ceramics. While generally stable, appropriate handling precautions are advised, particularly for fine powders, to avoid inhalation risks. Its unique combination of optical, electrical, and catalytic properties ensures tungsten oxide remains a vital material in modern technology, particularly for sustainable solutions like smart glass and pollution control.

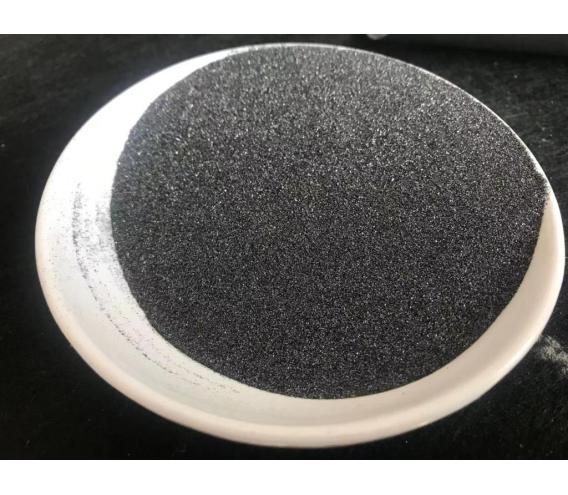

(tungsten oxide)

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)