Casting release spray is a vital tool for mold makers and crafters working with resin, concrete, plaster, or silicone. This specialized aerosol spray creates a non-stick barrier between a mold and the material being cast, ensuring clean demolding without damage to intricate details. It prevents materials from bonding to mold surfaces, saving time and reducing waste from stuck projects. Ideal for reusable molds, it extends their lifespan significantly.

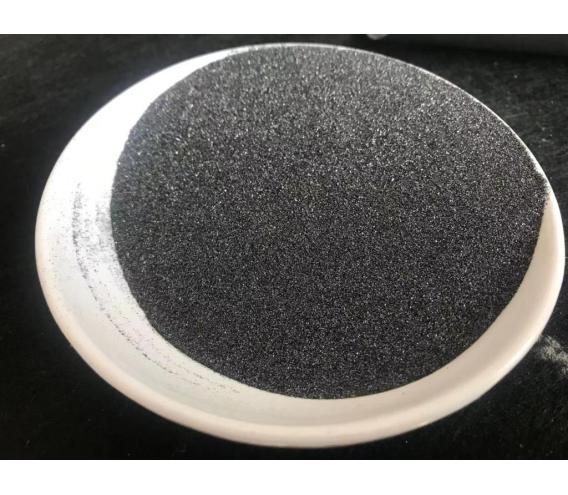

(casting release spray)

Using casting release spray is straightforward. First, ensure the mold is clean and completely dry. Shake the can vigorously for about 30 seconds to mix the formula. Hold the can 6-8 inches away and apply a thin, even coat over the entire mold surface. Avoid over-spraying, as pooling can cause imperfections. Allow the solvent to evaporate for 1-2 minutes before pouring your material. For complex molds, apply a second light coat after the first dries. Always work in a well-ventilated area and wear gloves to protect your skin.

Benefits include flawless surface finishes on casts, reduced breakage during removal, and compatibility with most mold materials like silicone, urethane, or metal. It’s non-reactive with resins or plasters, maintaining material integrity. For best results, store the spray in a cool, dry place and test on a small area if using a new mold type. Reapply every few casts if release performance weakens. Avoid using near open flames due to flammability.

(casting release spray)

This spray is indispensable for hobbyists and professionals alike, streamlining the casting process and ensuring consistent, high-quality results. Always follow manufacturer instructions for optimal safety and effectiveness.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)