Introduction to Aluminum Nitride

Aluminum nitride is a special product. It has one-of-a-kind residential or commercial properties that make it helpful in numerous fields. This product can hold up against high temperatures and is a superb conductor of warmth. These features make it perfect for electronics, illumination, and more. This post discovers what makes aluminum nitride special and exactly how it is made use of today.

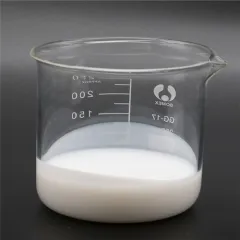

(TRUNNANO Aluminum Nitride Powder)

Make-up and Manufacturing Refine

Aluminum nitride is made from light weight aluminum and nitrogen. These aspects are integrated under regulated conditions to create a strong bond.

To make light weight aluminum nitride, pure light weight aluminum is heated with nitrogen gas. The response forms a powder. This powder is after that pushed right into forms or sintered to produce solid pieces. Special procedures can adjust the pureness and residential or commercial properties of the end product. The outcome is a flexible material on-line in various applications. Its thermal conductivity and electric insulation make it stand out.

Applications Across Different Sectors

Light weight aluminum nitride locates its usage in numerous markets as a result of its distinct residential properties. In electronic devices, it is utilized in semiconductors and circuits because it carries out heat well, which assists amazing gadgets. This avoids overheating and extends the life of digital parts. In aerospace, engineers value light weight aluminum nitride for its toughness and thermal conductivity, utilizing it in sensing units and actuators. Clinical gadgets take advantage of its capability to carry out heat efficiently and stand up to deterioration, making it risk-free for use in clinical settings. The automotive sector makes use of light weight aluminum nitride in electric vehicles to handle warm in batteries and power electronic devices, contributing to automobile safety and security and performance.

Market Fads and Growth Drivers

The need for aluminum nitride is climbing as technology advances. New technologies improve exactly how it is made, lowering expenses and increasing quality. Advanced testing guarantees materials function as anticipated, helping produce much better products. Companies embracing these innovations use higher-quality light weight aluminum nitride. As electronic devices come to be advanced, the requirement for reliable air conditioning services grows. Customers now understand a lot more concerning the advantages of light weight aluminum nitride and seek items that utilize it. Brands highlighting light weight aluminum nitride attract even more consumers. Advertising and marketing efforts educate customers regarding its advantages.

Challenges and Limitations

One obstacle is the price of making light weight aluminum nitride. The process can be pricey. However, the benefits usually exceed the expenses. Products made with light weight aluminum nitride last longer and perform much better. Companies must reveal the value of light weight aluminum nitride to justify the cost. Education and marketing aid below. Some worry about the safety and security of aluminum nitride. Correct handling is important to play it safe. Research continues to ensure its risk-free usage. Policies and guidelines regulate its application. Clear interaction about security constructs trust fund.

Future Leads: Technologies and Opportunities

The future looks intense for light weight aluminum nitride. A lot more study will find brand-new ways to use it. Innovations in materials and modern technology will improve its performance. Industries seek better solutions, and light weight aluminum nitride will certainly play a key role. Its capacity to perform warm and withstand high temperatures makes it useful. New developments might open additional applications. The capacity for development in various industries is significant.

End of Paper

( TRUNNANO Aluminum Nitride Powder)

This variation simplifies the structure while keeping the content specialist and interesting. Each area concentrates on certain elements of aluminum nitride, ensuring clarity and ease of understanding.

Distributor

TRUNNANO is a supplier of boron nitride with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about frame aluminium, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

Tags: aluminum nitride,al nitride,aln aluminium nitride

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us

Error: Contact form not found.