Zirconium disilicide, chemical formula ZrSi2, represents a significant intermetallic compound within materials science. This refractory material boasts a characteristic orthorhombic crystal structure. Its defining properties make it highly valuable for demanding applications. ZrSi2 exhibits an exceptionally high melting point, exceeding 2200°C, making it suitable for extreme thermal environments. It demonstrates good thermal stability and maintains reasonable thermal conductivity. Furthermore, zirconium disilicide is known for its good electrical conductivity, a property not always found in refractory ceramics. It possesses considerable hardness and inherent chemical stability, particularly against oxidation at elevated temperatures compared to some silicides, though protection is often still needed for very long durations.

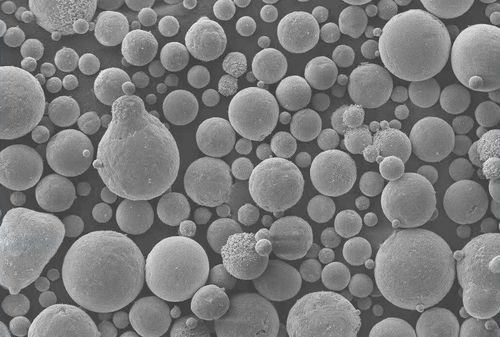

(zirconium disilicide)

(zirconium disilicide)

The primary application arena for zirconium disilicide lies in the semiconductor industry. It serves as a crucial contact material, forming low-resistance ohmic contacts with silicon in integrated circuits. Its compatibility with silicon processing and favorable electrical properties are key advantages here. Beyond microelectronics, ZrSi2 finds use in high-temperature structural components within aerospace and energy sectors, such as furnace elements or protective coatings, capitalizing on its thermal stability and strength. Research also explores its potential in thermoelectric devices for converting heat directly into electricity, leveraging its conductivity characteristics. While not as widely used as molybdenum disilicide in heating elements, zirconium disilicide occupies important niches where its specific combination of electrical and thermal properties is essential. Its role in enabling advanced semiconductor technology underscores its industrial importance.

Inquiry us

if you want to want to know more, please feel free to contact us.