How to Paint Stamped Concrete: A Quick Guide

(how to paint stamped concrete)

Stamped concrete adds texture and style to outdoor spaces, but over time, its color may fade. Painting stamped concrete revitalizes its appearance. Follow these steps for a professional finish.

Clean the Surface: Start by removing dirt, grease, or debris. Use a pressure washer or stiff brush with a concrete cleaner. Let the surface dry completely—usually 24–48 hours.

Repair Cracks: Fill small cracks or holes with a concrete patching compound. Smooth it evenly and let it cure as per the product instructions.

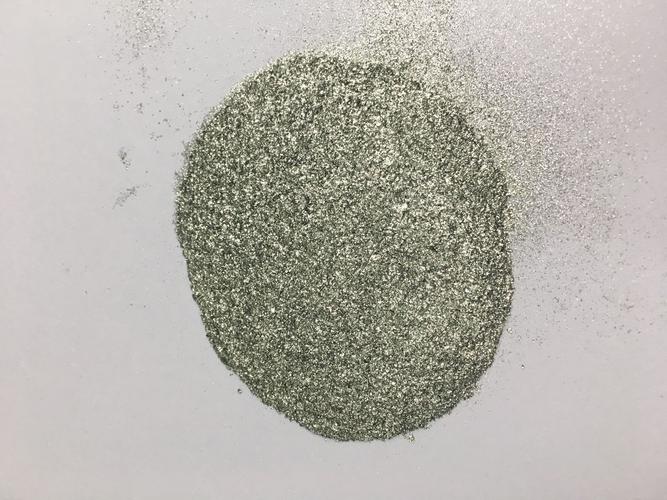

Etch the Concrete: Apply a concrete etcher (muriatic acid or phosphoric acid solution) to open the pores for better paint adhesion. Rinse thoroughly and allow it to dry.

Prime the Surface: Use a high-quality concrete primer to ensure the paint bonds well. Apply with a roller or brush, covering the entire area. Let the primer dry as directed.

Apply Paint: Choose acrylic or epoxy-based concrete paint for durability. Stir the paint well, then use a roller for large areas and a brush for textured details. Apply thin, even coats. Let the first coat dry (check the label for time), then add a second coat if needed.

Seal the Surface: Protect the paint with a concrete sealer. Opt for a non-yellowing, UV-resistant formula. Apply with a roller in thin layers, allowing proper drying time between coats.

Tips: Avoid painting in direct sunlight or extreme temperatures. Check weather forecasts to prevent rain from ruining fresh paint. Test colors on a small area first.

(how to paint stamped concrete)

Maintain the finish by reapplying sealer every 1–2 years. With proper prep and care, your painted stamped concrete will stay vibrant and durable for years.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)