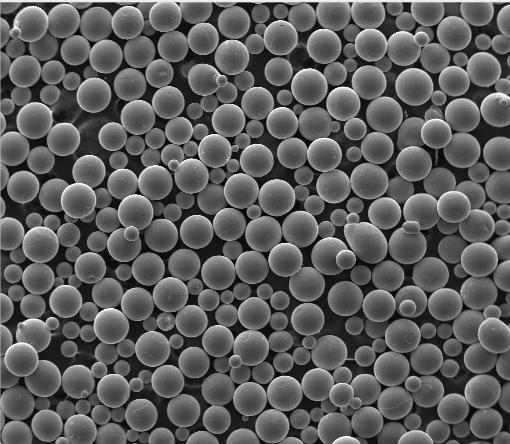

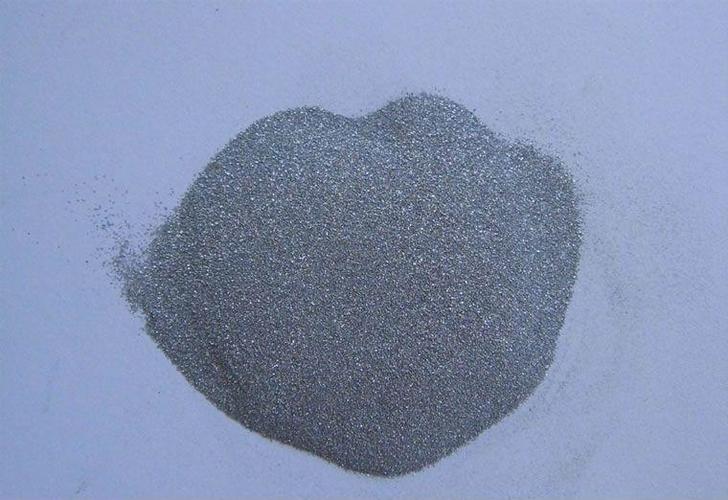

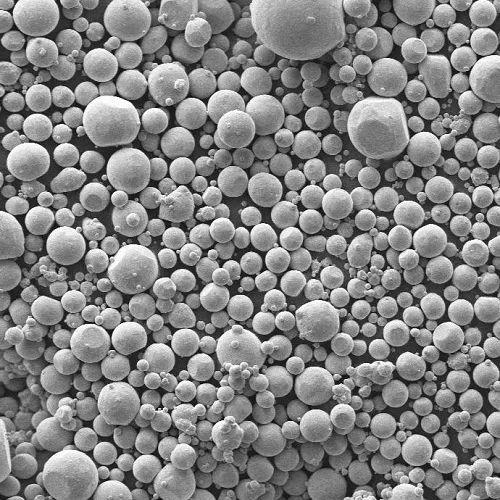

Powder release agents are essential in concrete construction for ensuring smooth, defect-free surfaces during demolding. These dry, fine-particle formulations create a barrier between concrete and formwork, preventing adhesion and minimizing surface damage. Commonly made from natural or synthetic materials like fatty acids, polymers, or silicates, they offer a mess-free alternative to liquid agents, ideal for vertical or intricate molds.

(powder release agent for concrete)

A key advantage of powder release agents is their ease of application. They are dusted directly onto formwork surfaces using brushes, sprayers, or manual methods, requiring no mixing. This reduces preparation time and waste while providing consistent coverage. Their dry nature eliminates runoff risks, making them suitable for indoor or confined spaces. Additionally, many powder agents are eco-friendly, free from volatile organic compounds (VOCs), and safe for workers.

Proper application ensures optimal performance. Surfaces must be clean and dry before applying a thin, even layer. Excess powder should be brushed off to avoid residue on finished concrete. Storage in cool, dry conditions prevents clumping. Compatibility with formwork materials—steel, wood, or plastic—is critical to avoid staining or reaction.

Powder agents enhance productivity by reducing cleaning time and formwork reuse cycles. They improve surface aesthetics by minimizing air pockets or honeycombing. Cost-effective and low-maintenance, they are favored in precast concrete, architectural projects, and large-scale industrial applications.

When selecting a powder release agent, consider project-specific factors: curing time, weather resistance, and desired finish. Safety gear like masks and gloves is recommended during handling. Always test the product on small sections before full use.

(powder release agent for concrete)

In summary, powder release agents streamline concrete demolding, enhance surface quality, and support sustainable practices. Their efficiency and versatility make them a vital tool for achieving professional results in modern construction.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)