Introduction to Polycarboxylate Water Reducers: A Game-Changer in Modern Concrete Modern Technology

Polycarboxylate water reducers (PCEs) have emerged as one of the most sophisticated class of superplasticizers in concrete formulation, revolutionizing the method designers design high-performance construction materials. Unlike typical naphthalene or lignosulfonate-based admixtures, PCEs offer remarkable dispersion efficiency, downturn retention, and compatibility with a vast array of cementitious systems. Their one-of-a-kind molecular style enables specific control over rheology and workability, making them essential in generating ultra-high-performance concrete (UHPC), self-consolidating concrete (SCC), and sustainable green building remedies throughout global framework tasks.

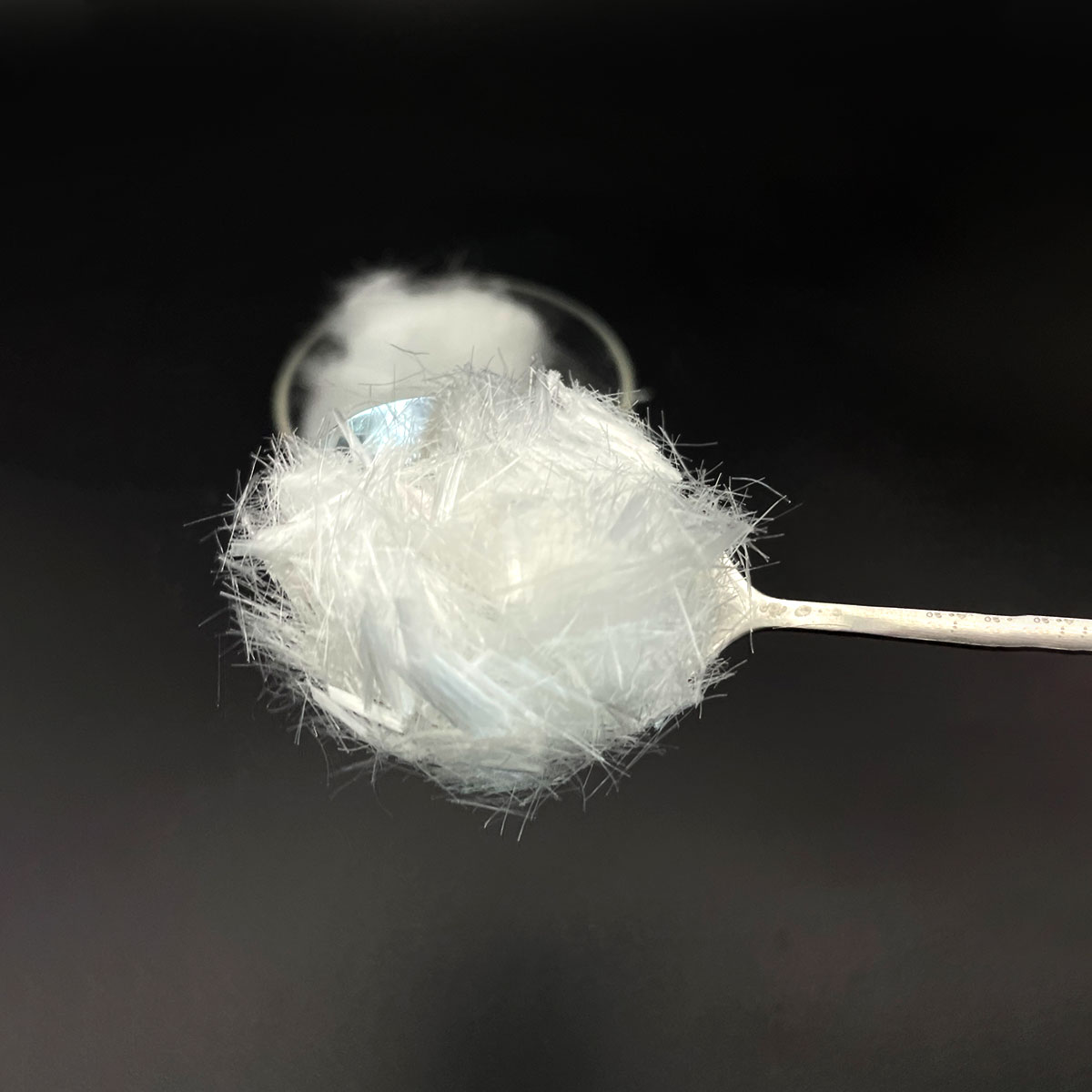

(Superliasticizer)

Molecular Framework and Device of Action

The efficiency of polycarboxylate water reducers comes from their comb-like copolymer framework, containing a major chain with pendant polyethylene glycol (PEG) side chains. This configuration enables solid electrostatic repulsion and steric obstacle in between concrete particles, preventing agglomeration and enhancing flowability without extreme water web content. Unlike traditional plasticizers that count exclusively on fee stabilization, PCEs make use of both electrostatic and steric devices– enabling greater dosing versatility, longer depression retention, and improved early-age toughness growth. This dual-action mechanism is vital to achieving liquid yet secure concrete mixes even under tough problems.

Advantages Over Standard Superplasticizers

Polycarboxylate water reducers exceed older-generation superplasticizers in multiple facets. Contrasted to sulfonated naphthalene formaldehyde (SNF) and melamine formaldehyde (SMF) polymers, PCEs display reduced dose requirements, better compatibility with blended concretes, and decreased level of sensitivity to sulfate material. They likewise reduce bleeding and partition while maintaining exceptional cohesiveness in fresh concrete. In addition, PCEs are a lot more environmentally friendly, as they do not launch formaldehyde throughout blending– a known carcinogen related to some conventional admixtures. These advantages make PCEs the favored choice for modern-day, high-efficiency concrete production.

Duty in Sustainable and Eco-Friendly Concrete Development

With raising focus on reducing the carbon impact of building and construction products, polycarboxylate water reducers are playing a main role in allowing lasting concrete modern technologies. By allowing significant reductions in water-to-cement proportions, PCEs sustain using extra cementitious products (SCMs) such as fly ash, slag, and calcined clay– decreasing dependence on Portland concrete, a major source of CO two emissions. In addition, their capacity to promote low-energy blending and prolonged pumping ranges improves power efficiency on building sites. Developments in bio-based and recyclable PCE variations are further straightening these admixtures with circular economic climate and net-zero goals in the constructed environment.

Applications Across High-Performance Construction Sectors

The adaptability of polycarboxylate water reducers has led to extensive fostering across critical building industries. In bridge decks and tunnel linings, PCE-modified concrete guarantees dense, nonporous frameworks with boosted longevity against chemical assault and freeze-thaw cycles. Precast and prestressed concrete components take advantage of fast toughness gain and reduced formwork cycle times. In overseas and aquatic design, PCEs add to chloride-resistant blends that extend life span in hostile settings. Meanwhile, building applications utilize PCE-enhanced SCC for elaborate formwork and revealed coatings, demonstrating both useful and visual benefits.

Technological Innovations and Next-Generation Formulations

Ongoing study is increasing the capabilities of polycarboxylate water reducers through molecular design, hybrid solutions, and clever admixture systems. Customized PCE structures with regulated molecular weight, side-chain thickness, and useful teams are being developed to optimize efficiency in specific concrete systems and environmental problems. Hybrid PCEs incorporating thickness modifiers or set accelerators are resolving particular niche requirements in 3D-printed concrete and cold-weather concreting. In addition, stimuli-responsive PCEs that adapt to temperature level or pH modifications throughout hydration are emerging, providing real-time performance tuning for complex architectural applications.

Difficulties and Compatibility Concerns in Practical Usage

( Concrete Addtives)

In spite of their many advantages, polycarboxylate water reducers face difficulties related to seal irregularity, ambient conditions, and interaction with other admixtures. Cement chemistry– including alkali web content, sulfate levels, and excellence– can dramatically influence PCE efficiency, causing uncertain depression loss or setting delays. Compatibility concerns may additionally develop when made use of alongside retarders, accelerators, or air-entraining representatives, necessitating cautious formula adjustments. Area workers must also handle dose precision, as overdosing can cause extreme blood loss or surface area problems. Dealing with these complexities calls for robust quality control methods and continual advancements in admixture compatibility testing.

Market Trends and Worldwide Market Characteristics

The worldwide market for polycarboxylate water reducers is experiencing stable development, driven by need for high-performance concrete in Asia-Pacific, North America, and Europe. China leads in production and usage, supported by large infrastructure financial investments and progressing requirements for sturdy building. Trick international chemical vendors are expanding into emerging markets in Africa and Latin America, where urbanization and housing demand are climbing. Strategic collaborations in between admixture makers and concrete technology companies are accelerating item innovation and electronic combination. In addition, regulative shifts towards greener construction practices are enhancing the long-term dominance of PCEs in the admixture landscape.

Future Expectation: Assimilation with Digital and Smart Construction Systems

Looking ahead, polycarboxylate water reducers will play an important role fit the future of smart and automated building. Integration with Structure Details Modeling (BIM) systems will make it possible for predictive admixture optimization based upon real-time job data. IoT-enabled dispensing systems and AI-driven mix adjustment tools will boost consistency and reduce product waste on job websites. Bio-inspired and carbon-negative PCE by-products are expected to emerge, aligning with sustainability requireds throughout the construction value chain. As concrete progresses right into a smarter, extra adaptable material, PCEs will remain at the core of this makeover, driving effectiveness, efficiency, and environmental duty in international facilities development.

Provider

Cabr-Concrete is a supplier of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high quality Concrete Admixture, please feel free to contact us and send an inquiry.

Tags: superplasticizer, water reducer, water reducing agent, concrete additives

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us

Error: Contact form not found.