Hydroxypropyl methylcellulose (HPMC) is a versatile synthetic polymer derived from plant cellulose, widely recognized for its role in pharmaceuticals, food additives, and dietary supplements. As a supplement, HPMC serves as a soluble fiber, promoting digestive health and supporting weight management. Unlike natural fibers, HPMC is non-digestible, meaning it passes through the gut without adding calories, making it a popular choice for those seeking low-calorie dietary solutions.

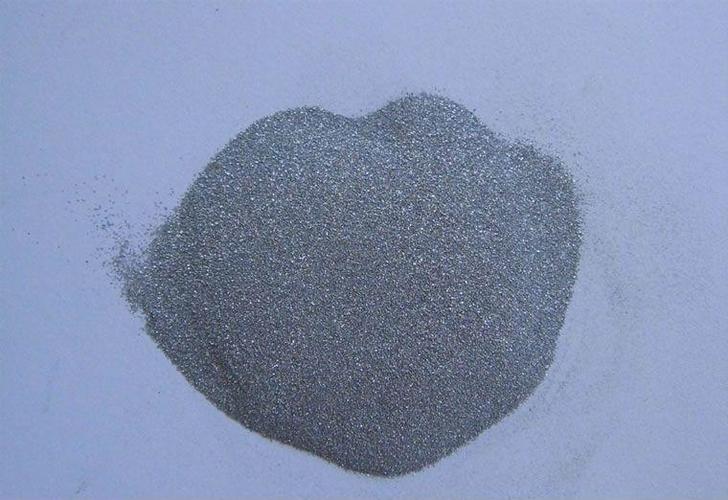

(hydroxypropyl methylcellulose supplement)

Primarily, HPMC works by absorbing water in the digestive tract, forming a gel-like substance that slows digestion. This mechanism aids in regulating bowel movements, alleviating constipation, and improving overall gut health. Additionally, the gel formation creates a sense of fullness, which can reduce appetite and calorie intake, supporting weight loss efforts. For individuals with dietary restrictions, HPMC is ideal—it’s vegan, gluten-free, and allergen-friendly.

Safety is a key advantage. The FDA classifies HPMC as Generally Recognized as Safe (GRAS), with minimal side effects when used appropriately. However, improper use—such as inadequate water intake—may cause temporary bloating or discomfort. To avoid issues, start with small doses (typically 1-2 grams daily) and gradually increase intake while drinking plenty of fluids. Always consult a healthcare provider before adding HPMC to your regimen, especially if you have gastrointestinal conditions or take medications, as fiber can interfere with drug absorption.

In supplements, HPMC is often found in capsule form or as a powder mixed into beverages. Its neutral taste and texture make it easy to incorporate into daily routines. Beyond gut and weight benefits, emerging research explores its potential in managing cholesterol and blood sugar levels, though more studies are needed.

(hydroxypropyl methylcellulose supplement)

For those seeking a plant-based, low-impact fiber supplement, hydroxypropyl methylcellulose offers a practical, science-backed option. Prioritize quality products from reputable brands, follow dosage guidelines, and pair with a balanced diet for optimal results.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)