1. Molecular Style and Colloidal Basics of Ultrafine Zinc Stearate Emulsions

1.1 Chemical Composition and Surfactant Habits of Zinc Stearate

(Ultrafine Zinc Stearate Emulsions)

Zinc stearate, chemically defined as zinc bis(octadecanoate) [Zn(C ₁₇ H ₃₅ COO)TWO], is an organometallic compound identified as a metal soap, developed by the reaction of stearic acid– a saturated long-chain fat– with zinc oxide or zinc salts.

In its strong type, it functions as a hydrophobic lubricant and release agent, however when processed right into an ultrafine emulsion, its utility expands dramatically because of improved dispersibility and interfacial task.

The particle features a polar, ionic zinc-containing head team and two long hydrophobic alkyl tails, providing amphiphilic attributes that enable it to function as an inner lube, water repellent, and surface modifier in diverse material systems.

In liquid emulsions, zinc stearate does not liquify but forms secure colloidal dispersions where submicron particles are stabilized by surfactants or polymeric dispersants versus gathering.

The “ultrafine” designation refers to droplet or fragment sizes usually below 200 nanometers, typically in the variety of 50– 150 nm, which considerably enhances the particular area and sensitivity of the spread phase.

This nanoscale dispersion is vital for accomplishing consistent distribution in intricate matrices such as polymer thaws, coverings, and cementitious systems, where macroscopic agglomerates would certainly compromise performance.

1.2 Emulsion Formation and Stablizing Mechanisms

The prep work of ultrafine zinc stearate solutions entails high-energy dispersion methods such as high-pressure homogenization, ultrasonication, or microfluidization, which break down coarse particles right into nanoscale domains within a liquid constant phase.

To prevent coalescence and Ostwald ripening– procedures that destabilize colloids– nonionic or anionic surfactants (e.g., ethoxylated alcohols, sodium dodecyl sulfate) are employed to reduced interfacial tension and supply electrostatic or steric stabilization.

The selection of emulsifier is vital: it has to be compatible with the intended application environment, preventing disturbance with downstream procedures such as polymer curing or concrete setting.

Additionally, co-emulsifiers or cosolvents may be presented to make improvements the hydrophilic-lipophilic balance (HLB) of the system, guaranteeing lasting colloidal security under differing pH, temperature, and ionic stamina problems.

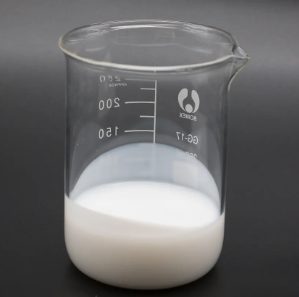

The resulting solution is normally milklike white, low-viscosity, and easily mixable with water-based formulas, making it possible for smooth integration into commercial assembly line without customized devices.

( Ultrafine Zinc Stearate Emulsions)

Correctly developed ultrafine emulsions can continue to be secure for months, resisting phase separation, sedimentation, or gelation, which is vital for consistent performance in massive production.

2. Handling Technologies and Particle Dimension Control

2.1 High-Energy Dispersion and Nanoemulsification Techniques

Achieving and maintaining ultrafine bit dimension requires accurate control over power input and procedure parameters during emulsification.

High-pressure homogenizers run at pressures surpassing 1000 bar, compeling the pre-emulsion through slim orifices where extreme shear, cavitation, and disturbance piece bits into the nanometer array.

Ultrasonic processors produce acoustic cavitation in the fluid tool, creating localized shock waves that disintegrate accumulations and advertise consistent bead circulation.

Microfluidization, an extra recent improvement, uses fixed-geometry microchannels to produce constant shear areas, making it possible for reproducible fragment size reduction with narrow polydispersity indices (PDI < 0.2).

These innovations not just decrease bit dimension however likewise enhance the crystallinity and surface area uniformity of zinc stearate fragments, which influences their melting habits and interaction with host products.

Post-processing steps such as filtering may be utilized to eliminate any kind of residual crude bits, ensuring product consistency and stopping defects in sensitive applications like thin-film layers or shot molding.

2.2 Characterization and Quality Control Metrics

The efficiency of ultrafine zinc stearate solutions is directly linked to their physical and colloidal properties, requiring rigorous analytical characterization.

Dynamic light spreading (DLS) is regularly used to determine hydrodynamic size and dimension circulation, while zeta potential analysis evaluates colloidal stability– values past ± 30 mV typically show good electrostatic stablizing.

Transmission electron microscopy (TEM) or atomic pressure microscopy (AFM) offers direct visualization of fragment morphology and dispersion quality.

Thermal evaluation methods such as differential scanning calorimetry (DSC) identify the melting point (~ 120– 130 ° C) and thermal deterioration account, which are essential for applications involving high-temperature processing.

Furthermore, stability testing under sped up conditions (raised temperature, freeze-thaw cycles) makes certain service life and toughness during transport and storage space.

Manufacturers likewise assess practical efficiency with application-specific tests, such as slip angle measurement for lubricity, water contact angle for hydrophobicity, or dispersion harmony in polymer composites.

3. Functional Roles and Performance Systems in Industrial Systems

3.1 Inner and External Lubrication in Polymer Processing

In plastics and rubber production, ultrafine zinc stearate emulsions act as highly efficient interior and external lubes.

When included into polymer melts (e.g., PVC, polyolefins, polystyrene), the nanoparticles move to user interfaces, minimizing thaw thickness and rubbing between polymer chains and handling tools.

This lowers power consumption throughout extrusion and shot molding, minimizes die accumulation, and enhances surface coating of shaped parts.

As a result of their tiny size, ultrafine bits spread more consistently than powdered zinc stearate, preventing localized lubricant-rich zones that can weaken mechanical residential or commercial properties.

They also function as outside launch representatives, forming a slim, non-stick movie on mold surface areas that promotes part ejection without deposit build-up.

This dual performance boosts manufacturing performance and item top quality in high-speed manufacturing environments.

3.2 Water Repellency, Anti-Caking, and Surface Modification Effects

Beyond lubrication, these solutions give hydrophobicity to powders, coatings, and construction products.

When put on seal, pigments, or pharmaceutical powders, the zinc stearate forms a nano-coating that drives away moisture, preventing caking and improving flowability during storage and handling.

In building finishings and renders, incorporation of the solution improves water resistance, reducing water absorption and enhancing resilience against weathering and freeze-thaw damage.

The mechanism includes the positioning of stearate molecules at interfaces, with hydrophobic tails exposed to the atmosphere, producing a low-energy surface that withstands wetting.

Additionally, in composite materials, zinc stearate can change filler-matrix communications, enhancing diffusion of inorganic fillers like calcium carbonate or talc in polymer matrices.

This interfacial compatibilization reduces heap and boosts mechanical efficiency, specifically in impact stamina and prolongation at break.

4. Application Domains and Emerging Technical Frontiers

4.1 Building And Construction Products and Cement-Based Systems

In the construction market, ultrafine zinc stearate solutions are significantly used as hydrophobic admixtures in concrete, mortar, and plaster.

They minimize capillary water absorption without endangering compressive toughness, thereby boosting resistance to chloride access, sulfate assault, and carbonation-induced corrosion of reinforcing steel.

Unlike standard admixtures that might influence establishing time or air entrainment, zinc stearate emulsions are chemically inert in alkaline settings and do not conflict with concrete hydration.

Their nanoscale dispersion makes certain consistent protection throughout the matrix, even at low dosages (usually 0.5– 2% by weight of concrete).

This makes them perfect for infrastructure projects in seaside or high-humidity regions where long-lasting durability is vital.

4.2 Advanced Production, Cosmetics, and Nanocomposites

In sophisticated production, these solutions are used in 3D printing powders to improve circulation and reduce moisture level of sensitivity.

In cosmetics and personal treatment items, they function as texture modifiers and water-resistant agents in structures, lipsticks, and sunscreens, providing a non-greasy feeling and improved spreadability.

Emerging applications include their usage in flame-retardant systems, where zinc stearate functions as a synergist by advertising char development in polymer matrices, and in self-cleaning surfaces that integrate hydrophobicity with photocatalytic activity.

Research is likewise exploring their combination right into clever finishes that respond to ecological stimuli, such as moisture or mechanical tension.

In recap, ultrafine zinc stearate emulsions exhibit how colloidal design transforms a traditional additive into a high-performance practical product.

By reducing fragment size to the nanoscale and supporting it in liquid diffusion, these systems accomplish superior uniformity, sensitivity, and compatibility throughout a broad spectrum of commercial applications.

As needs for performance, resilience, and sustainability expand, ultrafine zinc stearate solutions will remain to play a crucial role in allowing next-generation products and procedures.

5. Vendor

RBOSCHCO is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality chemicals and Nanomaterials. The company export to many countries, such as USA, Canada, Europe, UAE, South Africa, Tanzania, Kenya, Egypt, Nigeria, Cameroon, Uganda, Turkey, Mexico, Azerbaijan, Belgium, Cyprus, Czech Republic, Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand, Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a leading nanotechnology development manufacturer, RBOSCHCO dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for sulfur zinc oxide soap, please send an email to: sales1@rboschco.com

Tags: Ultrafine zinc stearate, zinc stearate, zinc stearate emulsion

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us

Error: Contact form not found.