Tungsten Trioxide WO3 Essential Facts

(tungsten 4 oxide)

Chemical compound tungsten trioxide WO3 appears as a yellow powder or crystalline solid. It’s a key member of the transition metal oxide family known for unique properties. Its stability and non toxicity make it suitable for diverse applications.

Electrochromism defines WO3. Applying a small voltage alongside ions like lithium causes it to reversibly change color typically from transparent yellow to deep blue. This principle powers smart windows dynamically controlling light and heat entering buildings enhancing energy efficiency significantly.

WO3 serves as an excellent gas sensor material. Its electrical conductivity changes detectably upon exposure to gases like nitrogen dioxide ammonia or hydrogen sulfide. This sensitivity enables reliable environmental monitoring and industrial safety systems.

Photocatalytic activity allows WO3 to degrade organic pollutants under light irradiation. It also finds use as a catalyst in various chemical reactions particularly oxidation processes important in industry. Its bandgap suits visible light activation.

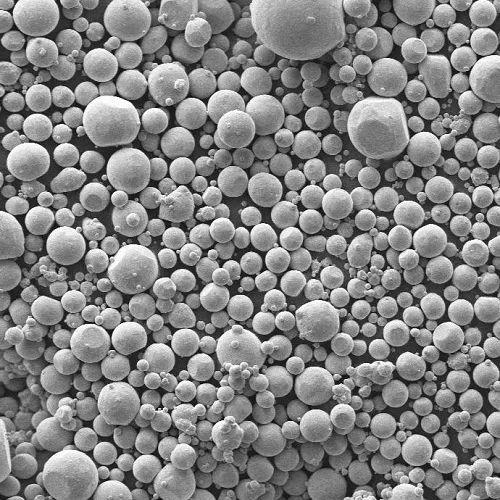

Synthesizing WO3 often involves calcining ammonium paratungstate or acidifying sodium tungstate solutions. Thin films vital for devices are created via sputtering sol gel processes or evaporation techniques.

Research actively explores nanostructured WO3 forms like nanowires and nanorods. These offer enhanced surface area boosting performance in sensing and catalysis. Doping with other elements further tunes its electronic and optical properties.

(tungsten 4 oxide)

Future applications target advanced energy storage systems like batteries and supercapacitors. WO3 based materials also show promise in next generation solar cells and advanced electronic devices. Its versatility continues driving materials science innovation.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)